| Basic Information |

Product Name |

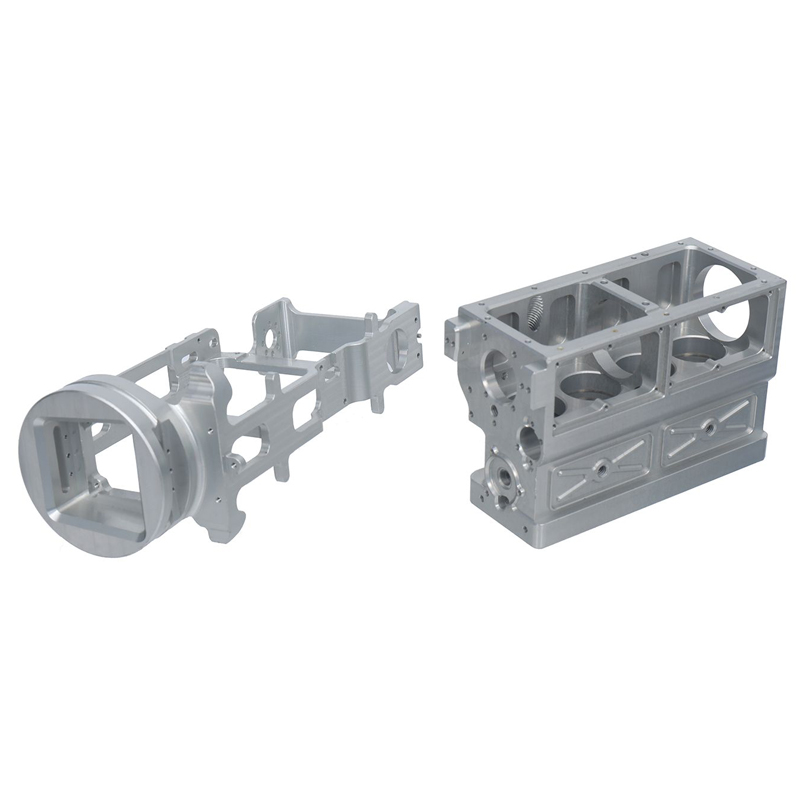

Precision Heat Dissipation End Cap Assembly for Industrial Servo Motors |

|

Applicable Motor |

150 Frame Size Servo Motors |

| Material & Surface Treatment |

Material |

Aluminum Alloy 6061-T6 |

|

Surface Treatment |

Hard Anodizing (Film thickness: 12~15μm; Salt spray resistance: ≥96h; Insulation resistance: ≥100MΩ) |

|

Thermal Conductivity |

≥180W/(m·K) |

| Dimension Specifications |

Front End Cap – Outer Diameter |

Φ150mm |

|

Front End Cap – Inner Shaft Hole Diameter |

Φ30mm (h6 precision tolerance) |

|

Front End Cap – Mounting Flange |

Φ130mm pitch circle, 4-M8 deep holes (Depth: 12mm; Thread precision: 6H) |

|

Front End Cap – Overall Thickness |

20mm |

|

Rear End Cap – Outer Diameter |

Φ150mm |

|

Rear End Cap – Central Shaft Hole Diameter |

Φ30mm (coaxial with front end cap) |

|

Rear End Cap – Central Mounting Holes |

6-M5 countersunk threaded holes (For bearing seat fixation; Depth: 8mm) |

|

Rear End Cap – Overall Thickness |

32mm (including extended fins) |

| Heat Dissipation Structure Parameters |

Front End Cap – Fin Quantity |

24 pieces (15° between adjacent fins) |

|

Front End Cap – Fin Dimensions |

Thickness: 2mm; Height: 15mm; Spacing: 4mm |

|

Front End Cap – Flow Guide Structure |

Curved guide grooves (Curvature radius: R50mm) on fin inner side |

|

Rear End Cap – Fin Quantity |

16 pieces (evenly distributed) |

|

Rear End Cap – Fin Dimensions |

Thickness: 3mm; Height: 22mm; Spacing: 6mm |

|

Rear End Cap – Lightening/Vent Holes |

6 Φ20mm waist-shaped holes (Balances lightweight & air flow) |

| Precision & Tolerance |

Flatness |

≤0.02mm (for front/rear end caps) |

|

Coaxiality (Assembly) |

≤0.015mm |

|

Key Fit Dimension Tolerance |

±0.01mm |

| Environmental & Performance Parameters |

Operating Temperature Range |

-40℃~125℃ |

|

Protection Class |

IP65 (with skeleton oil seal + sealing ring) |

|

Thermal Resistance |

≤0.7℃/W (With Φ150mm axial fan; End cap temperature rise ≤25K at rated power) |

Reviews

There are no reviews yet.