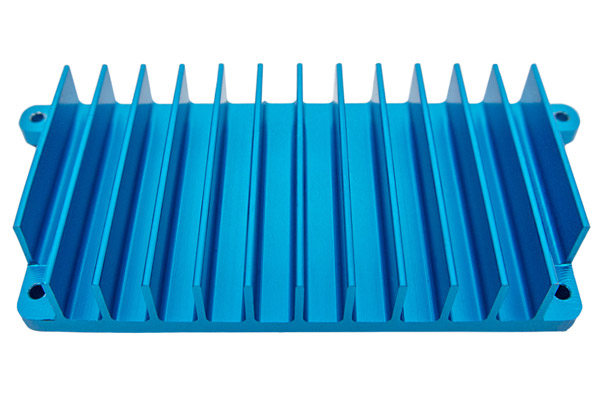

For the stable operation of industrial equipment—especially high-power, high-precision applications like industrial servo systems—heat sinks serve as core thermal management components. Their selection directly dictates equipment lifespan, operational efficiency, and reliability. As a manufacturer specializing in CNC precision machining, we leverage years of experience in custom heat sink fabrication to provide systematic, professional advice on key challenges businesses face when purchasing heat sinks, including material selection, process matching, supplier screening, and cost optimization.

I. Clarify Core Requirements for Custom Heat Sinks: The Fundamental Premise of Selection

1.1 Power Rating & Heat Load: Aligning with Core Custom Heat Sink Needs

1.2 Precision & Flatness Requirements: Key Indicators for Custom Heat Sinks

1.3 Batch Size & Delivery Needs: Efficiency Alignment for CNC Machined Heat Sinks

1.4 Structural & Installation Requirements: Core Customization Points for Custom Heat Sinks

1.5 Environmental Friendliness & Working Condition Adaptability: Scenario Matching Principles for Custom Heat Sinks

II. Material Selection for Custom Heat Sinks: Matching Optimal Cost-Effectiveness to Requirements

2.1 Aluminum Alloys: The Core Preferred Material for Custom Heat Sinks

- 1060 Aluminum Alloy (Sub-states: O-temper, H14-temper): Boasts high thermal conductivity (approximately 201 W/(m·K)) and high purity (≥99.6%). O-temper (annealed) is suitable for bending forming, while H14-temper (lightly work-hardened) enhances structural stability. Ideal for low-to-medium power (<10kW) applications requiring high thermal conductivity but moderate structural strength (e.g., standard electronic component heat sinks, household appliance heat sinks). Advantages: Excellent thermal conductivity, low processing difficulty, and cost-effectiveness (approximately $0.34/lb). Limitation: Low tensile strength (only 75MPa), unsuitable for high-precision or high-stress scenarios.

- 6061 Aluminum Alloy (Sub-states: T6-temper, T651-temper): Moderate thermal conductivity (approximately 155 W/(m·K)). T6-temper (solution heat-treated and artificially aged) achieves tensile strength of 310MPa; T651-temper (stress-relieved) is better suited for high-precision machining. Offers excellent structural strength and processing precision; deformation can be effectively controlled via stress relief and natural aging processes. Ideal for high-power (10-50kW) and high-precision scenarios (e.g., industrial servo heat sinks, special-shaped curved heat sinks). For heat sinks requiring 1mm wall thickness and structural stability, 6061-T651 is the optimal choice (cost: approximately $0.42/lb).

- 7075 Aluminum Alloy (Core State: T6-temper): A high-strength aluminum alloy with tensile strength of 503MPa and thermal conductivity of approximately 130 W/(m·K). Suitable for high-stress, high-vibration scenarios (e.g., military equipment heat sinks, high-speed motor heat structures). Limitations: High processing difficulty and cost (approximately $0.99/lb), requiring specialized tools and 5-axis machining; more common in small-batch customization.

- 5052 Aluminum Alloy (Core State: H32-temper): Thermal conductivity of approximately 140 W/(m·K) and tensile strength of 190MPa. Its key advantage is exceptional corrosion resistance (far superior to 1060/6061), making it ideal for harsh environments such as coastal areas and high-temperature/humidity conditions (e.g., marine equipment servo heat sinks, outdoor PV inverter heat sinks). Cost: Approximately $0.39/lb.

2.2 Auxiliary Materials: Special Function Adaptation for Custom Heat Sinks

- Copper Tubes (Sub-models: T2 Copper, TP2 Deoxidized Copper): T2 copper offers extremely high thermal conductivity (approximately 385 W/(m·K)) and low impurity content, specifically designed for water-cooled plate applications where it is integrated into aluminum substrates via pre-embedded bending to form efficient heat transfer channels. TP2 deoxidized copper (phosphorus content: 0.015-0.040%) exhibits excellent hydrogen embrittlement resistance, suitable for high-temperature, high-pressure water-cooled systems (e.g., high-power industrial servo water-cooled plates). Ensure tight fit between copper tubes and aluminum substrates to avoid gaps affecting heat transfer. In high-end scenarios, aluminum matrix composites (e.g., AlSiC) can replace pure copper, reducing costs by 40-60% while maintaining thermal conductivity of 80 W/mK.

- Stainless Steel (Sub-models: 316, 316L, 304): 316 stainless steel offers excellent corrosion and wear resistance (tensile strength: 485MPa), ideal for threaded parts requiring deburring in humid or corrosive environments. 316L (low-carbon 316, carbon content ≤0.03%) provides enhanced intergranular corrosion resistance, suitable for high-temperature corrosive environments (e.g., chemical equipment heat sinks). 304 stainless steel is more cost-effective (approximately $0.27/lb vs. $0.46/lb for 316) but offers slightly lower corrosion resistance, suitable for general mild-corrosion scenarios.

- Graphene Coatings/Microphase Change Materials (Sub-types): Hot auxiliary materials in 2025. Graphene coatings are available in water-based (suitable for room-temperature scenarios) and oil-based (temperature resistance ≤200℃) variants; spraying on aluminum plates reduces cold plate thickness by 30% and overall system volume. Microphase change materials include paraffin-based (phase change temperature: 20-60℃, suitable for electronic component heat dissipation) and metal-based (phase change temperature: 60-150℃, suitable for high-power equipment) types. They enable chip-level heat dissipation, reducing liquid cooling system load and lowering pump power consumption by 40%.

- Copper-Aluminum Composite Materials (Core Models: Cu/Al-1060, Cu/Al-6061): Aluminum-based with a 1-3mm copper cladding layer, combining copper’s high thermal conductivity (overall thermal conductivity: approximately 250 W/(m·K)) with aluminum’s lightweight properties. Cost falls between pure copper and aluminum alloys (approximately $0.67/lb), suitable for mid-range high-power scenarios (15-30kW) such as mid-range industrial servos and frequency converter heat sinks.

- Titanium Alloy (Core Model: Gr5 Ti-6Al-4V): Low thermal conductivity (approximately 6.7 W/(m·K)) but exceptional corrosion resistance (resistant to strong acids and alkalis) and high strength (tensile strength: 860MPa). Suitable for extreme corrosion environments (e.g., chemical strong acid heat dissipation). Requires heat dissipation enhancement structures (e.g., grooving + graphene coating) and is costly (approximately $7.30/lb), limited to special custom scenarios.

III. Process Selection for CNC Machined Heat Sinks: Balancing Precision, Efficiency, and Cost

Different processes correspond to varying levels of precision, production efficiency, and cost. Businesses should select the optimal process combination based on their needs (precision, batch size, structure):

3.1 Core Processing Technology: Application Scenarios & Advantages of Pure CNC Machining for Custom Heat Sinks

- Pure CNC Machining: As the core process for custom heat sinks, it fully adapts to diverse needs including small-batch/large-batch production, high precision, and special-shaped structures (e.g., diamond-shaped, curved heat sinks). It covers multiple scenarios such as industrial servos, NEV three-electric systems (motor controller water-cooled plates, battery pack heat sinks), PV inverter heat brackets, precision heat structures for medical equipment (e.g., MRI, CT devices), and high-stress heat components for military electronics. CNC milling, a key part of this process, includes face milling for flat base surface processing and end milling for fin forming and flow channel grooving—using 5-axis machining equipment enables precise forming of complex curved surfaces. The combination of “1.5mm large ball end mill roughing + small ball end mill finishing” improves milling efficiency while ensuring surface precision and flatness. For heat sinks with cylindrical features (e.g., threaded connectors, cylindrical heat pillars), CNC turning is integrated to guarantee roundness and surface smoothness, achieving seamless collaboration between milling and turning in custom fabrication. For example, using a 12mm white steel fine corrugated tool with parameters (4000rpm, feed rate 1500mm/min, 20mm height step full-depth cutting) achieves efficient and precise machining like “cutting tofu.” For large-batch production, unit processing costs can be further reduced via dedicated machine debugging and multi-station simultaneous machining.

3.2 High-Precision Auxiliary Processes: Strict Precision Assurance for Custom Heat Sinks

- 5-Axis Machining + Stress Control: For scenarios requiring extreme flatness and structural precision (e.g., high-end industrial servo heat sinks, water-cooled plates), 5-axis machining eliminates precision errors caused by multiple clamping. Combined with stress relief and natural aging processes, it effectively controls processing deformation and ensures long-term operational stability of heat sinks.

- Wire-Cutting Profiles: Wire cutting with 0.1A current achieves high-precision forming of heat sink profiles, suitable for scenarios requiring high edge precision (e.g., special-shaped mounting surfaces, precision connection parts). It avoids burrs or dimensional deviations on edges caused by conventional cutting processes.

- Eco-Friendly Deburring: Select suppliers with this capability. Mainstream 2025 technologies include laser deburring and ultrasonic deburring. High-end heat sinks, in particular, require complete removal of burrs from surfaces, holes, and tooth profiles to avoid affecting installation fit or causing equipment scratches, while complying with environmental production standards.

- Automated Welding & Sealing Processes: For complex structures like water-cooled plates, robotic brazing (yield rate increased from 75% to 98%) or laser welding (efficiency improved by 3x, leakage rate <1×10⁻⁹ Pa·m³/s) is recommended to replace traditional manual welding, significantly enhancing connection reliability.

- Surface Finishing: A critical post-processing step for custom heat sinks, directly affecting corrosion resistance, thermal conductivity, and appearance. Mainstream 2025 technologies include: Anodizing (type II/III, suitable for aluminum alloy heat sinks, improving wear resistance and corrosion resistance, compliant with MIL-A-8625 standard); Polishing (achieving surface roughness Ra ≤ 0.8μm, enhancing thermal conductivity by reducing contact resistance); Powder coating (providing electrical insulation and aesthetic appeal, ideal for household appliance or indoor equipment heat sinks); Chemical conversion coating (forming a thin protective film, improving adhesion for subsequent painting). For high-end scenarios like medical or marine equipment, environmentally friendly surface finishing processes (e.g., low-VOC anodizing) are preferred to meet strict environmental regulations.

3.3 Avoid Inefficient Processes: Pitfalls to Avoid for High-Precision Custom Heat Sinks

IV. Supplier Screening for Custom Heat Sinks: Core Guarantee for Customization Services

4.1 Custom Heat Sink Fabrication Capability: Core Evaluation Criterion

4.2 Process Control Capability: Detail Guarantee for CNC Machined Heat Sink Quality

4.3 Quality Inspection System: Avoiding Quality Risks for Custom Heat Sinks

4.4 Batch Delivery Capability: Matching Production Rhythms for CNC Machined Heat Sinks

4.5 Cost Optimization Capability: Key to Long-Term Cooperation for Custom Heat Sinks

V. Cost & Time Optimization for Custom Heat Sink Procurement: Core Practical Tips

- Batch Tiered Planning: Use pure CNC machining for rapid validation of small-batch samples. For large-batch orders, improve efficiency and reduce costs via supplier dedicated machine debugging and process standardization (e.g., fixed processing flows, multi-station simultaneous production). For multi-batch orders of the same model, negotiate with suppliers to reserve processing plans to shorten subsequent delivery times.

- Process Parameter Collaboration: Provide clear processing parameters to suppliers (e.g., 12mm white steel fine corrugated tool, 4000rpm, feed rate 1500mm/min) to avoid repeated debugging and improve efficiency. For curved or special-shaped structures, prioritize standardized parameters for 5-axis machining to reduce custom debugging time.

- Precise Material Matching: Avoid blind pursuit of high-spec materials. For low-to-medium power (<10kW) applications (e.g., small instrumentation, household appliance control boards), select 1060-O/H14 aluminum alloy. For high-power (10-50kW) scenarios (e.g., industrial servos, NEV three-electric systems, PV inverters), choose 6061-T651 aluminum alloy. For high-stress applications (e.g., military electronics, high-speed motors), opt for 7075-T6 aluminum alloy. For humid/mild-corrosion environments (e.g., outdoor PV equipment, marine servo heat sinks), select 5052-H32 aluminum alloy. For coastal/salt spray environments (e.g., marine electronics, offshore PV power plants), use 316 stainless steel or 5052 aluminum alloy. For high-pressure waste heat recovery (e.g., chemical plants, PV inverter waste heat utilization), choose Q345B low-carbon steel. For extreme corrosion environments (e.g., chemical strong acid environments, medical disinfection equipment), select Gr5 titanium alloy. For mid-range high-power scenarios (e.g., industrial frequency converters, mid-range servos), use copper-aluminum composite materials. For medical equipment (e.g., MRI, CT), prioritize 316L stainless steel for its corrosion resistance and hygiene, balancing cost and heat dissipation efficiency.

- Early Risk Avoidance: Clearly communicate high-precision requirements to suppliers to avoid inefficient processes like skiving. For complex structures such as water-cooled plates, confirm flow channel designs via CFD simulation in advance and use automated welding processes to ensure tightness, avoiding rework that wastes time and costs.

- Operation & Maintenance Cost Optimization: For high-power scenarios (>20kW), prioritize cold plate heat dissipation—though initial costs are higher, long-term maintenance costs are lower. Introduce 5G-based remote diagnostic capabilities to reduce O&M labor costs by 50%. Coating cold plate inner walls with PTFE (Teflon) extends service life from 5 to 10 years, reducing annual costs by 20%.