High-Performance Turbocharger Compressor Impeller for Engines

Description

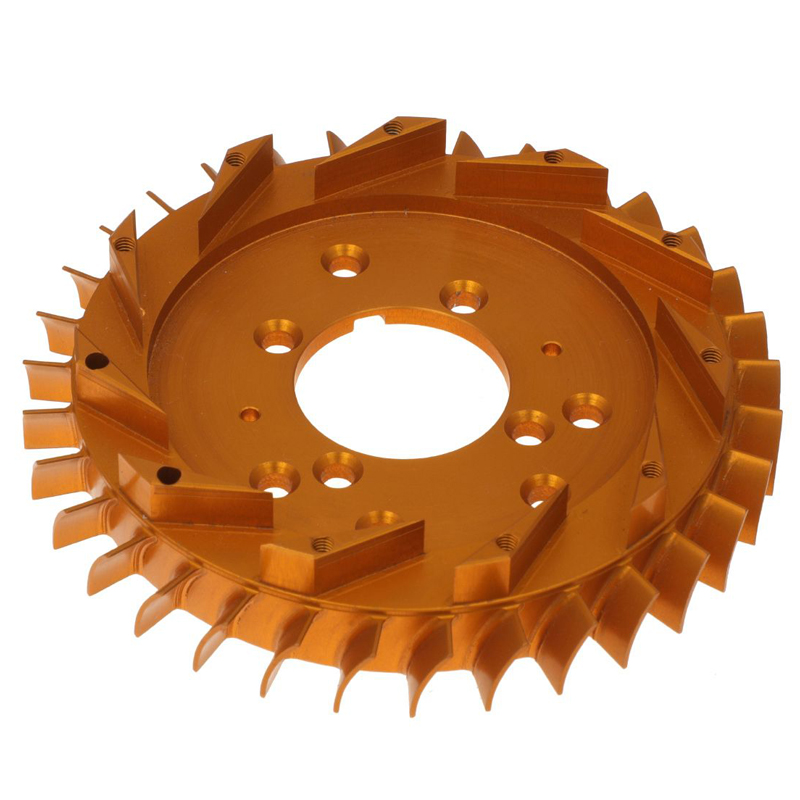

High-Precision Plastic Cooling Fan Impeller: Custom CNC Machining Solutions

Our High-Precision Plastic Cooling Fan Impeller is a core component tailored for industrial cooling and ventilation systems, integrating advanced CNC machining technology and high-performance plastic materials to deliver reliable and efficient heat dissipation solutions. Designed for medium and small cooling equipment, this impeller excels in scenarios such as industrial centrifugal fan cooling, micro motor heat dissipation, and ventilation of precision instruments, effectively enhancing equipment operating stability and extending service life.

We adopt premium plastic materials including glass fiber reinforced PA66 (PA66 GF30), PPS, and PVDF, which are selected based on different working conditions—PA66 GF30 for general scenarios, PPS for high-temperature environments, and PVDF for strong corrosion applications. The impeller is manufactured via 4-axis/5-axis simultaneous CNC milling, ensuring precise forming of curved blades and accurate positioning of shaft holes. With strict precision control (dimensional tolerance as low as ±0.01mm for shaft holes, dynamic balance grade up to G2.5), it operates stably without vibration even at high rotational speeds (up to 8000RPM for PPS material).

To meet diverse customer needs, we offer comprehensive customization services covering blade quantity (12-20 pieces), impeller diameter (φ50mm-φ250mm), and shaft hole diameter (φ8mm-φ20mm), supporting sample trial, small-batch production, and mass production with cost-effective solutions. All products comply with ISO9001:2015 and RoHS standards, and we provide free dynamic balance test reports and 3D drawing optimization suggestions to ensure perfect matching with customer equipment.

|

Category

|

Parameter Item

|

Standard Value / Service Capability

|

|---|---|---|

|

Basic Product Info

|

Product Name

|

High-Precision Plastic Cooling Fan Impeller

|

|

Core Application

|

Industrial centrifugal fan cooling / Micro motor heat dissipation / Ventilation equipment of precision instruments

|

|

|

Applicable Equipment Size Range

|

φ80mm-φ200mm (for medium and small cooling equipment)

|

|

|

CNC Machining Process

|

Machining Material

|

Glass Fiber Reinforced PA66 (PA66 GF30, default) / PPS (high-temperature demand) / PVDF (strong corrosion scenarios)

|

|

Machining Equipment

|

4-axis/5-axis CNC Machining Center (Haas/FANUC, with constant temperature module)

|

|

|

Machining Process

|

4-axis simultaneous milling (curved blade forming) + precision drilling (shaft hole positioning) + deburring (ultrasonic cleaning + manual finishing) + surface polishing

|

|

|

Surface Treatment

|

Plastic special anti-static coating (default) / Wear-resistant spraying / Custom color coating (optional)

|

|

|

Precision Control

|

Dimensional Tolerance

|

±0.03mm (blade profile); ±0.01mm (shaft hole positioning datum)

|

|

Geometric Tolerance

|

Roundness ≤0.005mm (shaft hole); Flatness ≤0.01mm (mounting end face)

|

|

|

Surface Roughness

|

Ra1.6μm (blade working surface); Ra3.2μm (non-mating surface)

|

|

|

Dynamic Balance Grade

|

G6.3 (suitable for ≤5000RPM normal-speed scenarios; G2.5 optional for high-speed demand)

|

|

|

Performance Guarantee

|

Maximum Adaptable Rotational Speed

|

≤5000RPM (PA66 GF30); ≤8000RPM (PPS)

|

|

Residual Dynamic Balance of Blades

|

≤2g·mm (stable operation without vibration in long-term use)

|

|

|

Mechanical Properties of Material

|

PA66 GF30: Tensile strength ≥180MPa; Heat resistance ≤120℃; PPS: Heat resistance ≤220℃, acid and alkali corrosion resistance

|

|

|

Customization Service

|

Size Customization Range

|

Blade quantity: 12-20 pieces; Impeller diameter: φ50mm-φ250mm; Shaft hole diameter: φ8mm-φ20mm

|

|

Batch Support

|

Sample (1-10 pcs) / Small batch (10-300 pcs) / Medium and large batch (300+ pcs, injection molding blank + CNC finishing for cost reduction)

|

|

|

Additional Services

|

1 free dynamic balance test report; 3D drawing optimization suggestions; Full-size machining supported by STEP/IGS/DXF format drawings

|

|

|

Testing Standard

|

Testing Equipment

|

3D Coordinate Measuring Machine (accuracy ±0.002mm) / Dynamic Balance Tester / Surface Roughness Tester / High-temperature Resistance Tester

|

|

Quality Standard

|

ISO9001:2015; RoHS certification; Complies with precision plastic machining industry standards for cooling equipment components

|

Additional information

| material |

|---|

Reviews

There are no reviews yet.