Precision CNC Machined Structural Frame for High-End Industrial Equipment

Description

Introduction to the Integrated Structural Assembly

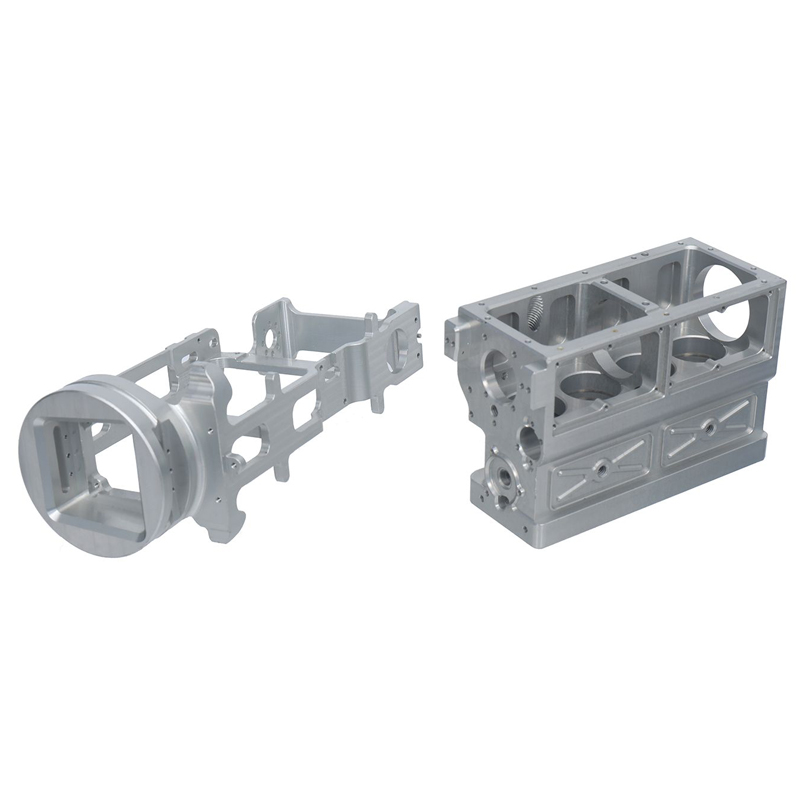

This precision CNC-machined assembly comprises two purpose-built components—the Front-End Extension Frame (Part-001) and Main Chamber Housing (Part-002)—engineered as a seamless, modular core structure for high-end industrial equipment.

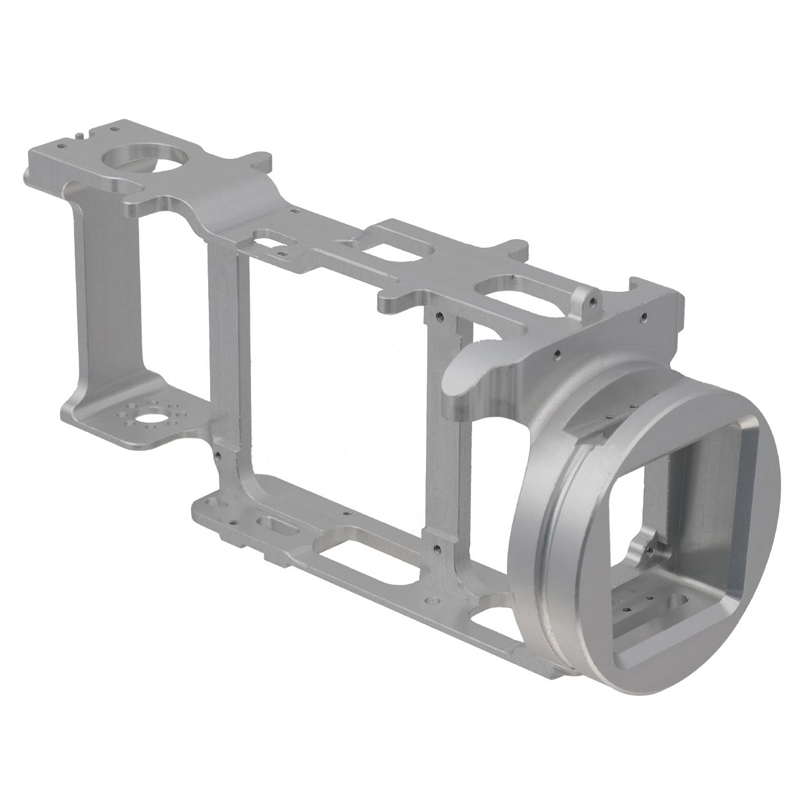

The Front-End Extension Frame features an open, weight-optimized skeleton design (with 4 long-strip weight-reduction windows) paired with a precision-machined circular datum interface. This balances exceptional structural rigidity with lightweight performance, while providing a coaxial connection point to align upstream system components.

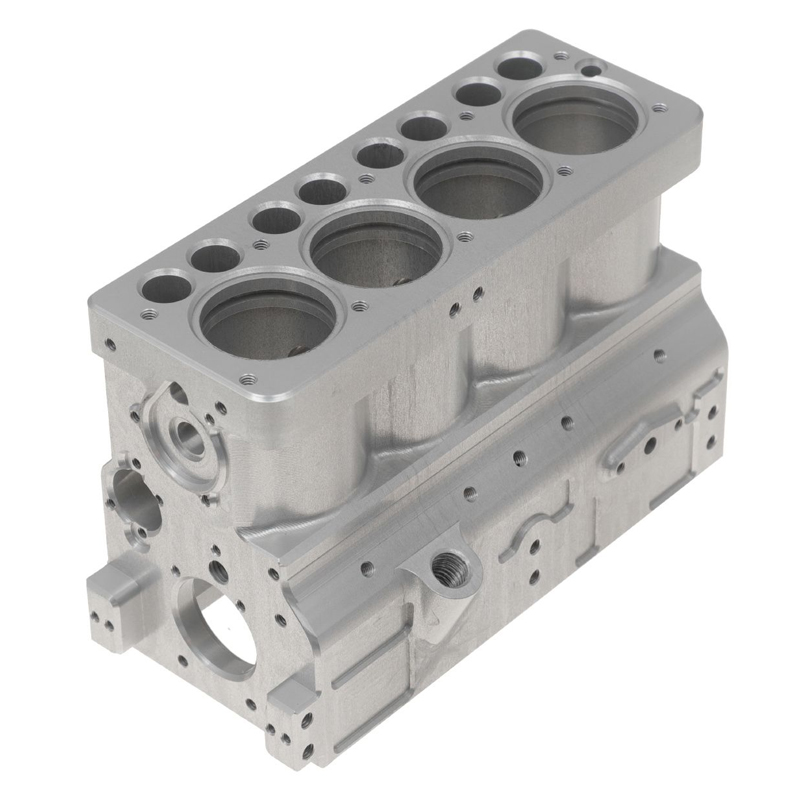

Complementing it, the Main Chamber Housing is a closed-cavity structure with 4 precisely arrayed internal chambers—serving as the primary mounting base for critical equipment components. Its tight-tolerance assembly face (Ra 1.6μm flatness) ensures perfect alignment with the Front-End Frame, forming a unified skeleton post-assembly.

Crafted from 6061-T6 aluminum alloy via multi-axis CNC milling (with >75% material removal rates), both parts undergo natural anodization/sandblasting for durability. When assembled (via torque-controlled M5 bolts), the unit achieves ≤0.03mm overall coaxiality, supporting rated static loads of ≥50kg along the axis direction. It is ideally suited for precision motion modules, high-end testing instruments, and custom automated systems.

Its modular design also accommodates tailored adjustments (dimensions, hole patterns, surface finishes) to match unique equipment specifications, making it a reliable, cost-efficient solution for integrating load-bearing, component mounting, and alignment functions in high-performance industrial setups.

Parameter Sheet 1: Left Component (Front-End Extension Frame)

| Item | Description | Value/Range |

|---|---|---|

| Basic Information | Component Name | Front-End Extension Frame |

| Part Number | Part-001 | |

| Material | Base Material Grade | Aluminum Alloy 6061-T6 |

| Material Density | 2.7g/cm³ | |

| Material Hardness | ≥95HB | |

| Overall Dimensions | Length × Width × Height | 180mm × 60mm × 250mm (Example) |

| Datum Interface Diameter | Φ80mm (Front Circular Interface) | |

| Machining Process | Primary Process | Precision 5-Axis CNC Milling |

| Material Removal Rate | ≥75% | |

| Surface Finish | Treatment Method | Natural Anodization (or Sandblasting) |

| Surface Roughness | Ra 1.6μm (Datum Surfaces) / Ra 3.2μm (Non-Datum Surfaces) | |

| Key Geometric Tolerances | Datum Interface Coaxiality | ≤0.02mm |

| Assembly Face Perpendicularity | ≤0.015mm (Relative to Datum Interface Axis) | |

| Frame Plane Parallelism | ≤0.02mm | |

| Functional Hole Details | Assembly Bolt Holes (Qty/Spec) | 6 pcs / M5×8mm Threaded Holes |

| Datum Locating Holes (Qty/Spec) | 2 pcs / Φ6H7 Pin Holes | |

| Weight Reduction Window Quantity | 4 pcs (Long Strip Shape) |

Parameter Sheet 2: Right Component (Main Chamber Housing)

| Item | Description | Value/Range |

|---|---|---|

| Basic Information | Component Name | Main Chamber Housing |

| Part Number | Part-002 | |

| Material | Base Material Grade | Aluminum Alloy 6061-T6 |

| Material Density | 2.7g/cm³ | |

| Material Hardness | ≥95HB | |

| Overall Dimensions | Length × Width × Height | 220mm × 100mm × 150mm (Example) |

| Assembly Opening Size | 82mm × 62mm (Matches Left Component Flange) | |

| Chamber Specifications | Functional Chamber Quantity | 4 pcs (Regular Array) |

| Single Chamber Depth | 50mm | |

| Machining Process | Primary Process | Precision 4-Axis + 3-Axis Hybrid CNC Milling |

| Material Removal Rate | ≥80% | |

| Surface Finish | Treatment Method | Natural Anodization (or Sandblasting) |

| Surface Roughness | Ra 1.6μm (Assembly Faces/Chamber Walls) / Ra 3.2μm (Outer Walls) | |

| Key Geometric Tolerances | Chamber Axis Coaxiality | ≤0.02mm (Relative to Assembly Datum Face) |

| Assembly Datum Face Flatness | ≤0.01mm | |

| Chamber Wall Perpendicularity | ≤0.015mm (Relative to Chamber Bottom Face) | |

| Functional Hole Details | Assembly Bolt Holes (Qty/Spec) | 6 pcs / M5×10mm Threaded Holes (Matches Left Component) |

| Internal Mounting Holes (Qty/Spec) | 8 pcs / Φ4.5mm Through Holes (For Component Fixing) | |

| Locating Pin Holes (Qty/Spec) | 2 pcs / Φ6H7 Pin Holes (Matches Left Component) |

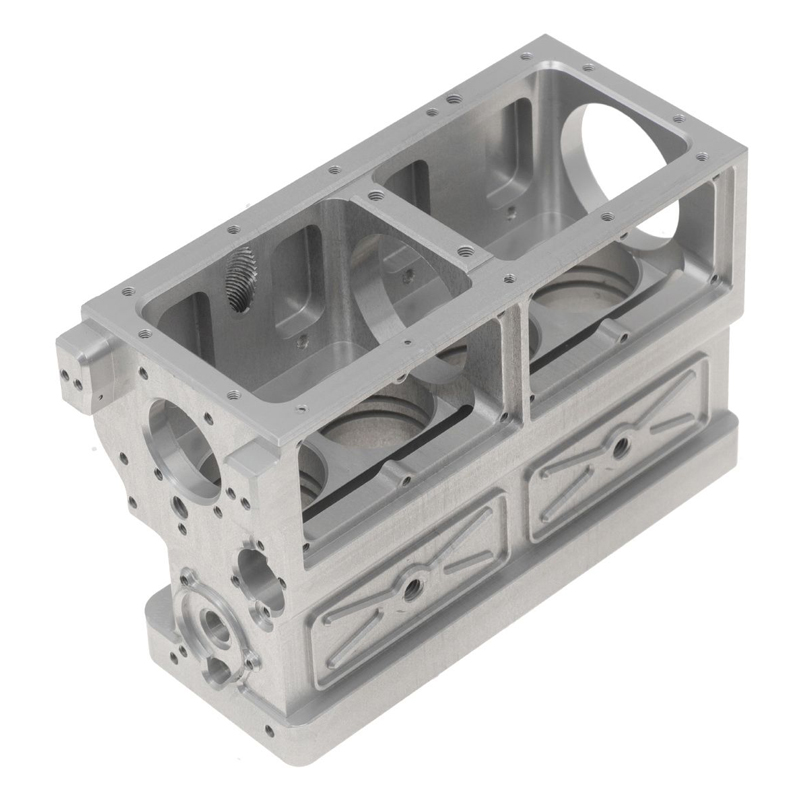

Parameter Sheet 3: Assembled Integrated Component

| Item | Description | Value/Range |

|---|---|---|

| Basic Information | Assembly Name | Front-End Extension + Main Chamber Integrated Structural Assembly |

| Assembly Number | Assembly-001 | |

| Assembly Details | Connection Method | M5 Hexagon Socket Bolt (Torque: 8N·m) |

| Overall Dimensions After Assembly | 320mm × 100mm × 250mm (Example) | |

| Post-Assembly Precision | Overall Axis Coaxiality | ≤0.03mm (Left Component Interface → Right Component Chamber) |

| Overall Mounting Datum Face Parallelism | ≤0.02mm | |

| Performance Specifications | Rated Static Load Capacity | ≥50kg (Along Axis Direction) |

| Operating Temperature Range | -20℃ ~ +80℃ | |

| Application Scenarios | Suitable Equipment Types | Precision Motion Modules / High-End Testing Instruments / Custom Precision Equipment |

| Inspection Requirements | Post-Assembly Inspection Items | Interface Gap (≤0.05mm), Geometric Tolerance Recheck, Load-Bearing Test |

Additional information

| material |

|---|

Be the first to review “Precision CNC Machined Structural Frame for High-End Industrial Equipment” Cancel reply

Reviews

There are no reviews yet.