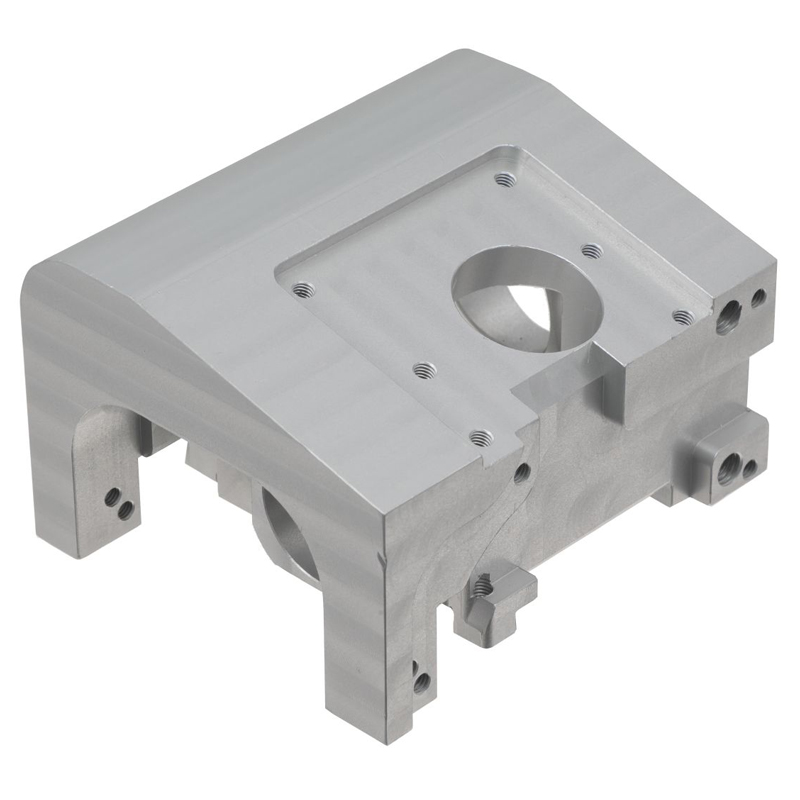

CNC Machined Aluminum Enclosure for Industrial Embedded Control Systems

Description

This CNC machined aluminum enclosure is designed for embedded control and industrial electronics applications, offering high structural rigidity, precise internal cavities, and flexible interface customization.

| Parameter Category | Specification / Details | Notes (Buyer-Focused) |

|---|---|---|

| Product Type | CNC Machined Aluminum Electronics Enclosure | Embedded control & industrial electronics |

| Application | Embedded Control Systems, Industrial Controllers, Automation Modules | Non-RF, non-microwave primary use |

| Material Options | Aluminum 6061-T6 (Standard), 6063, 7075 (Optional) | Good machinability & strength |

| Manufacturing Process | CNC Milling (3-axis / 4-axis / 5-axis) | Solid billet machining |

| Structure Type | One-piece machined housing with internal cavity | High rigidity, no welding |

| Dimensional Tolerance | ±0.01 mm (Standard), ±0.005 mm (Critical features) | Based on customer drawings |

| Internal Cavity Accuracy | ±0.01 mm | Suitable for PCB & module installation |

| Flatness / Parallelism | ≤ 0.02 mm | Ensures proper cover & panel fit |

| Mounting Features | Threaded holes, countersunk holes, internal mounting points | For PCB, modules, covers |

| Interface Openings | Custom rectangular / circular cut-outs | Display windows, I/O panels |

| Surface Finish (Standard) | CNC machined finish (Ra 1.6–3.2 μm) | Clean industrial appearance |

| Surface Treatment (Optional) | Anodizing, Hard Anodizing, Bead Blasting, Powder Coating | Color & corrosion resistance |

| Assembly Compatibility | Top cover / side panel installation | Easy maintenance & integration |

| EMC Consideration | Aluminum enclosure provides basic EMI shielding | Not designed as RF cavity |

| Operating Environment | Industrial indoor environment | Control cabinets, equipment housing |

| Prototype & MOQ | Prototype supported, Low-volume production | Ideal for custom projects |

| Drawing Formats Accepted | STEP / STP, IGES, X_T, DWG, PDF | 3D + 2D preferred |

| Quality Inspection | CMM, Calipers, Height Gauge | Inspection report available |

| Lead Time | 7–15 working days (depends on complexity) | Faster for prototypes |

Additional information

| material |

|---|

Reviews

There are no reviews yet.