Custom Precision CNC Electric Motor Housing | Aluminum Industrial-Grade CNC Machined Motor Enclosures for Industrial Automation Equipment

Description

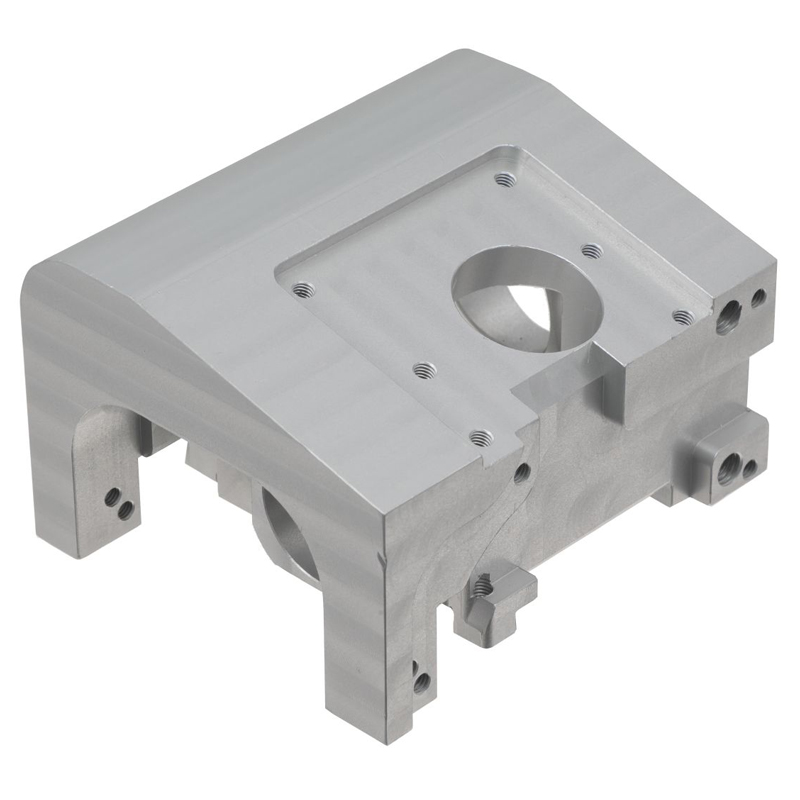

Precision CNC Electric Motor Housing: Industrial-Grade Machined Component for High-Performance Applications

Our CNC Electric Motor Housing is a core precision component engineered for industrial electric motors, leveraging advanced CNC machining technologies to deliver reliability, durability, and optimal performance. Crafted primarily from high-quality aluminum alloys (6061/6063/7075) — with stainless steel (304/316) and carbon steel options available — this housing balances lightweight design, excellent heat dissipation, and structural stability, making it ideal for demanding industrial environments.

Through integrated CNC milling, turning, and drilling processes, we achieve tight dimensional tolerances of ±0.01mm to ±0.05mm and surface roughness as low as Ra 0.8, ensuring seamless compatibility with motor rotors, stators, and other internal components. The housing features precision-machined mounting holes, a smooth internal cavity, and customizable size ranges (50mm-500mm in length/width, 30mm-300mm in height) to fit diverse motor specifications, supported by full customization based on 2D/3D client drawings.

To enhance corrosion resistance, wear resistance, and aesthetics, we offer a range of surface treatments including anodizing (clear/silver/black), powder coating, electrophoresis, and sandblasting. Widely applied in industrial automation equipment motors, HVAC systems, automotive auxiliary motors, and smart manufacturing machinery, this component is backed by ISO 9001-certified quality control — including CMM inspection and dimensional testing reports — to guarantee consistency across small-batch and mass production runs.

Whether you require a prototype for validation or large-scale production, our one-stop CNC machining service supports MOQs as low as 1 piece, with flexible lead times (3-7 working days for samples, 7-15 for mass production) and full-process traceability. Designed to protect motor internal components from dust, vibration, and external impact while optimizing heat dissipation, our CNC Electric Motor Housing is the trusted choice for manufacturers seeking precision, durability, and customization in motor packaging solutions.

|

Item

|

Specifications

|

Remarks

|

|---|---|---|

|

Product Name

|

CNC Electric Motor Housing (CNC Machining Parts)

|

Customizable per client drawings

|

|

Machining Service

|

CNC Milling, CNC Turning, CNC Drilling, Precision Cutting, Deburring

|

Full-process precision machining support

|

|

Material

|

Aluminum Alloy (6061/6063/7075), Stainless Steel (304/316), Carbon Steel (Customizable)

|

Aluminum alloy recommended for light weight & heat dissipation

|

|

Machining Precision

|

Dimensional Tolerance: ±0.01mm – ±0.05mm; Surface Roughness: Ra 0.8 – Ra 3.2

|

Meets industrial motor component precision standards

|

|

Size Range

|

Customizable (Length/Width: 50mm – 500mm; Height: 30mm – 300mm, Support Custom Drawings)

|

Over-range sizes available on request

|

|

Surface Treatment

|

Anodizing (Clear/Silver/Black), Powder Coating, Electrophoresis, Sandblasting, Polishing

|

Anodizing for corrosion resistance & aesthetics

|

|

Application

|

Industrial Electric Motors, Automation Equipment Motors, HVAC Motors, Automotive Auxiliary Motors

|

Widely used in industrial automation field

|

|

MOQ

|

1 Piece (Small Batch & Mass Production Available)

|

Sample order acceptable for quality testing

|

|

Quality Control

|

ISO 9001 Certified, CMM Inspection, Dimensional Testing Report

|

Quality report provided upon request

|

|

Lead Time

|

3-7 Working Days (Sample); 7-15 Working Days (Mass Production)

|

Rush order service available

|

Additional information

| material |

|---|

Reviews

There are no reviews yet.