Precision CNC Machined Fixture Block | Custom Jig & Mounting Component

Description

Precision CNC Machined Fixture Block

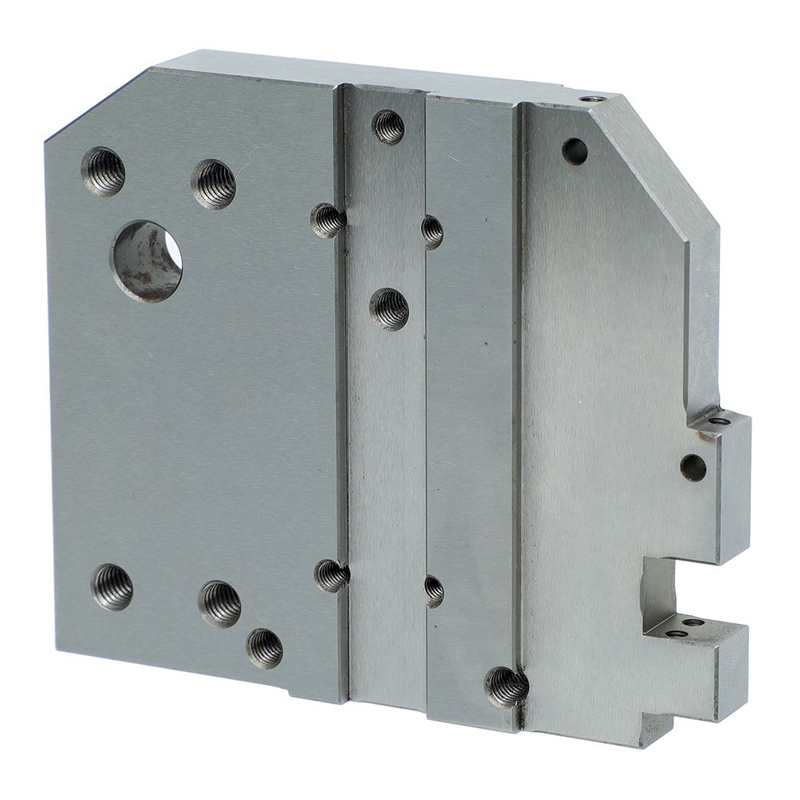

This precision CNC machined fixture block is a custom-engineered component designed for accurate mounting, positioning, and alignment within industrial equipment and fixture systems. Manufactured using high-precision CNC milling processes, the part is optimized for applications where mechanical stability, repeatable positioning, and dimensional accuracy are critical.

The fixture block features multiple threaded holes and stepped locating surfaces, enabling secure multi-directional mounting and precise mechanical engagement with mating components. Its non-standard geometry and function-driven hole layout indicate a fully customized design, tailored to specific equipment requirements rather than mass-produced or catalog parts.

Commonly used in fixture and jig systems, industrial automation equipment, and custom machinery assemblies, this CNC machined block serves as a structural interface between machine bases, modules, or functional units. The robust block-type structure provides excellent rigidity, helping maintain alignment under load and during repeated assembly cycles.

Material options such as aluminum alloys, stainless steel, or tool steel can be selected based on strength, weight, corrosion resistance, and operating environment requirements. Surface finishes including anodizing or black oxide are available to enhance durability and service life.

This component is ideal for prototype development as well as low- to medium-volume production, supporting OEM and custom engineering projects. With tight tolerance control and comprehensive inspection processes, the fixture block ensures reliable performance in precision mechanical systems.

| Category | Specification | Notes |

|---|---|---|

| Part Name | Precision CNC Machined Fixture Block | Custom non-standard component |

| Industry Application | Fixture & Jig System / Industrial Automation Equipment | Used for positioning, mounting and alignment |

| Manufacturing Process | CNC Milling, CNC Drilling, Tapping | Multi-axis CNC machining |

| Material Options | Aluminum 6061 / 7075, Stainless Steel 304 / 316, Tool Steel | Material selectable per application |

| Part Type | Custom Fixture Block / Mounting Base | Not a standard catalog part |

| Key Features | Multiple threaded holes, stepped positioning surfaces, precision-machined faces | Designed for mechanical positioning and fixation |

| Dimensional Tolerance | ±0.01 mm (or as required) | Critical dimensions controlled |

| Surface Finish | Machined finish / Anodizing / Black Oxide | Optional surface treatment |

| Mounting Method | Bolt-on installation via threaded holes and locating steps | Provides repeatable positioning |

| Production Volume | Prototype to Low & Medium Volume | Suitable for custom projects |

| Customization | Fully customizable based on drawings or samples | OEM / ODM supported |

| Quality Control | CMM Inspection, Dimensional & Visual Inspection | Inspection report available |

| File Formats Accepted | STEP / STP / IGES / PDF / DWG | 3D model preferred |

Reviews

There are no reviews yet.