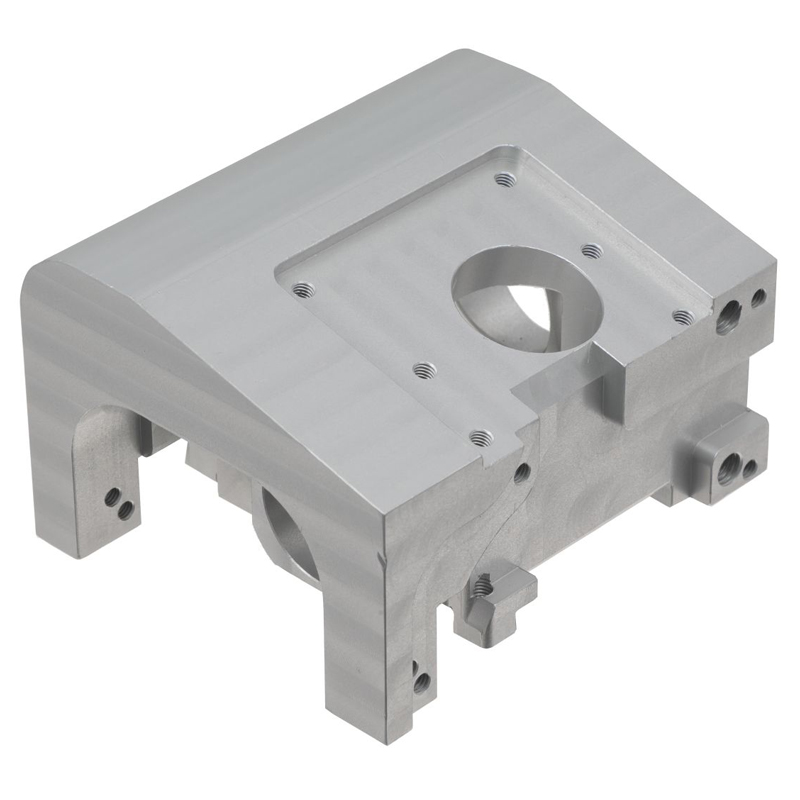

CNC Linear Actuator Housing: Custom Aluminum High-Precision CNC Machined for Robotic Motion Module

Description

| Parameter Category | Specification / Details |

|---|---|

| Product Name | CNC Linear Actuator Housing (Robotic Motion Module Application) |

| Material | 6061-T6 Aluminum Alloy (suitable for lightweight design, excellent machinability, and structural strength required in motion control systems) |

| Core Machining Process | CNC Vertical Milling (including drilling, tapping, and precision hollow milling) |

| Typical Size Range | Length: 150–200 mmWidth: 40–50 mmHeight: 35–45 mm(Custom sizes available) |

| Machining Precision | Dimensional tolerance: ±0.02 mmHole position tolerance: ±0.01 mm(meets linear actuator assembly accuracy requirements) |

| Surface Finish | Clear Anodizing (natural anodization for enhanced wear resistance and corrosion protection) |

| Mounting Feature Specs | Threaded holes: M3 / M4 (for motors, sensors, and internal components)Locating holes: Ø5–Ø8 mm |

| Applicable Industries | Industrial RoboticsAutomated Motion Control Equipment |

| Custom Service Support | Size adjustmentHole layout optimizationMaterial replacement (e.g., 7075 aluminum alloy) |

CNC Linear Actuator Housing for Robotic Motion Module Product Introduction

Our CNC Linear Actuator Housing is a high-precision structural component specifically engineered for robotic motion modules, leveraging advanced CNC machining technology to deliver reliable performance and exceptional compatibility for industrial automation applications. As a critical part of linear actuator systems, this housing serves as the core load-bearing and protective structure, ensuring stable operation of robotic motion mechanisms in high-demand industrial environments.

Premium Material Selection for Robotic Application Demands

Crafted from 6061-T6 aluminum alloy, the housing strikes an optimal balance between lightweight properties and structural strength—essential for robotic motion modules that require both agility and load-bearing capacity. The 6061-T6 alloy also boasts excellent machinability, allowing for precise shaping of complex structures while maintaining consistent material integrity. For specialized high-strength requirements, we offer material customization options such as 7075 aluminum alloy, adapting to diverse robotic motion module design needs.

High-Precision CNC Machining for Seamless Assembly

Employing state-of-the-art CNC vertical milling technology, the housing undergoes processes including drilling, tapping, and precision hollow milling to achieve superior dimensional accuracy. With a dimensional tolerance of ±0.02mm and a hole position tolerance of ±0.01mm, it ensures perfect alignment with linear actuator motors, sensors, and other components, eliminating assembly gaps and enhancing the overall stability of the robotic motion system. The precision-machined hollow structure not only reduces the overall weight of the module but also optimizes heat dissipation during operation.

Optimized Design for Robotic Motion Module Compatibility

The housing features a tailored design with M3/M4 threaded holes and φ5-φ8mm locating holes, specifically configured to secure linear actuator components and adapt to the installation requirements of robotic motion modules. The integrated structural frame provides robust protection for internal components against external dust, vibration, and impact, extending the service life of the linear actuator in harsh industrial settings. Its typical size range (Length: 150-200mm; Width: 40-50mm; Height: 35-45mm) can be fully customized to match the specific dimensional parameters of different robotic motion module designs.

Surface Treatment & Customization Capabilities

Finished with clear anodization, the housing exhibits excellent wear resistance and corrosion resistance, ensuring long-term reliable performance in humid, dusty, or chemically exposed industrial environments. Beyond standard specifications, we offer comprehensive custom services, including size adjustment, hole layout optimization, material replacement, and alternative surface treatments (e.g., hard anodization, powder coating) to meet the unique technical requirements of various industrial robotics and automated motion control equipment projects.

Wide Application in Industrial Automation

Ideal for industrial robotics, automated motion control equipment, and precision mechanical systems, this CNC Linear Actuator Housing plays a vital role in enhancing the motion accuracy, stability, and durability of robotic modules. Whether for collaborative robots, industrial handling robots, or automated production line motion mechanisms, our product provides a high-quality, customizable solution that supports the efficient operation of modern industrial automation systems.

Additional information

| material |

|---|

Reviews

There are no reviews yet.