In the field of precision CNC machining, material selection is directly linked to product performance, safety, and cost budgets. Recently, a client consulted whether it is possible to replace the material of coffee machine parts from aluminum alloy to stainless steel, and how the cost would change. Targeting this common machining demand, this article details the feasibility of material replacement and the core reasons for cost differences, combined with the industry characteristics of CNC machining.

Table of Contents

ToggleFeasibility of Material Replacement: Food-Grade Stainless Steel is the Core Premise

As components that directly come into contact with food or beverages, coffee machine parts must prioritize safety standards in material selection, which is the core premise for material replacement. Replacing aluminum alloy with stainless steel is fully technically feasible, but not all stainless steels are suitable for this scenario:

- Food-grade 304 stainless steel or 316 stainless steel must be used. These two materials have excellent corrosion resistance, which can effectively avoid rusting, oil leakage, and other issues during use, meeting the safety requirements for food-contact materials;

- Ordinary stainless steel, due to insufficient corrosion resistance, is prone to rust after long-term contact with moisture and beverage residues. This not only affects the product appearance but also may contaminate beverages. Therefore, it must never be used for the processing of coffee machine parts and other food-related components.

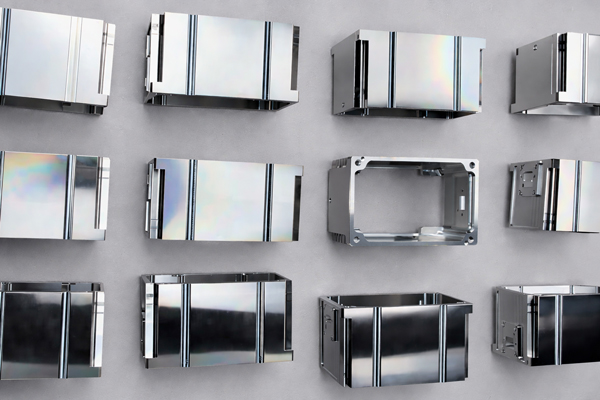

From the perspective of processing technology, CNC equipment is capable of handling high-hardness materials. As long as suitable tools and machining parameters are matched, both 304 and 316 stainless steel can achieve precision machining, fully meeting the required appearance quality and dimensional accuracy of coffee machine parts.

Core Reasons for Soaring Costs: Dual Impacts of Material and Processing Efficiency

Regarding the cost issue that clients are most concerned about, the answer is clear: after replacing aluminum alloy with food-grade stainless steel, the overall machining cost will increase by at least twice, and even more in some scenarios. This cost difference does not arise out of nowhere but is jointly determined by material characteristics and processing logic, mainly stemming from two core factors:

Material Cost: Cost Doubling Due to Density Difference

The cost of the material itself is the primary expense. From a physical property perspective, the density of stainless steel is nearly three times that of aluminum alloy for the same volume—this means that manufacturing the same part requires almost three times the weight of stainless steel compared to aluminum alloy.

In the raw material procurement market, the unit weight price of food-grade 304 and 316 stainless steel is inherently higher than that of aluminum alloy. Coupled with the doubling of weight, the material procurement cost alone will be close to three times that of aluminum alloy, becoming an important basis for cost increase.

Processing Time: Increased Hardness Impairs Production Efficiency

One of the core advantages of aluminum alloy is its relatively soft material. During CNC machining, the cutting resistance of tools is small, the processing fluency is high, and a series of processes such as milling, drilling, and polishing can be completed at a relatively fast speed, resulting in extremely high production efficiency.

In contrast, 304 and 316 stainless steel are much harder than aluminum alloy, causing greater wear on tools. During processing, it is necessary to reduce the cutting speed and optimize the tool path to ensure machining accuracy and avoid tool damage. To achieve the same appearance quality and dimensional accuracy as aluminum alloy parts, the processing time for stainless steel parts will be about twice that of aluminum alloy.

In the CNC machining industry, processing time is directly linked to processing costs, and the reduction in efficiency will inevitably lead to a significant increase in labor costs.

Conclusion: A Trade-Off Between Cost and Demand

Overall, the technical feasibility of replacing aluminum alloy with food-grade stainless steel for coffee machine parts is fully established, but it is necessary to accept the reality of a substantial cost increase—the combination of material costs and processing time costs results in an overall cost that is at least twice that of aluminum alloy parts.

For clients, whether to choose material replacement is essentially a trade-off between demand and cost: if prioritizing product corrosion resistance, safety, and service life, and there are no strict restrictions on cost budgets, 304 or 316 stainless steel is a better choice; if cost is the core consideration and aluminum alloy can already meet the usage requirements, maintaining the original material is more economical.

In precision CNC machining, material selection is never a one-dimensional decision. Understanding the characteristics and cost logic of different materials is crucial to maximizing cost-effectiveness while meeting product requirements. Whether processing aluminum alloy or stainless steel, choosing a professional CNC machining manufacturer and optimizing materials and processes according to product scenarios is the key to ensuring product quality and cost control.