In everyday industrial manufacturing, many people are unfamiliar with—or curious about—the concept of a temperature-controlled workshop. However, when it comes to machining high-precision aluminum alloy components, it is common to hear experienced professionals say:

“This kind of part really needs to be machined in a temperature-controlled environment.”

Is this merely an industry convention, or is there solid engineering science behind it? In this article, we take a practical and engineering-based look at why temperature control plays such a critical role in high-precision aluminum CNC machining.

Table of Contents

TogglePrecision at the Micron Level: Where Temperature Becomes a Deciding Factor

When dimensional tolerances reach ±0.01 mm (10 microns) or tighter, machining enters the micron-level precision domain. At this scale, many factors that are negligible in conventional machining become decisive—and temperature variation is one of the most influential.

Thermal Expansion of Materials and Machines

Both aluminum alloys and CNC machine tools share a fundamental physical property: thermal expansion.

- Machine thermal deformation

During high-speed operation, spindles, ball screws, and linear guides generate heat. Even minimal temperature changes can cause structural deformation that directly impacts machining accuracy. - Workpiece thermal instability

Cutting generates localized heat at the tool–workpiece interface. If the workshop temperature is unstable—due to air drafts, open doors, or uneven cooling—the part dimensions may continuously shift during machining. - Measurement inconsistency

High-precision parts are typically inspected using coordinate measuring machines (CMMs), which themselves require a stable temperature reference. Measurements taken under fluctuating thermal conditions cannot be reliably compared.

For high-precision machining, temperature control is not optional—it is foundational infrastructure.

Matching Environment to Requirements: Not Every Part Needs a Temperature-Controlled Room

A common misconception is that all aluminum CNC machining requires a temperature-controlled environment. In reality, the requirement depends on one key factor: the final dimensional tolerance of the part.

Ultra-High Precision (Tolerance ≤ ±0.01 mm): Temperature Control Is Mandatory

Parts in this category are commonly used in:

- Precision optical equipment

- Medical device core components

- Aerospace and advanced research instruments

At this level, even slight thermal fluctuations are unacceptable. Manufacturing is typically performed in dedicated, clean, temperature-controlled rooms, where temperature is maintained around 20°C ±0.5°C, with controlled humidity.

From fine machining to final inspection, the entire process takes place in a stable thermal environment to eliminate external interference.

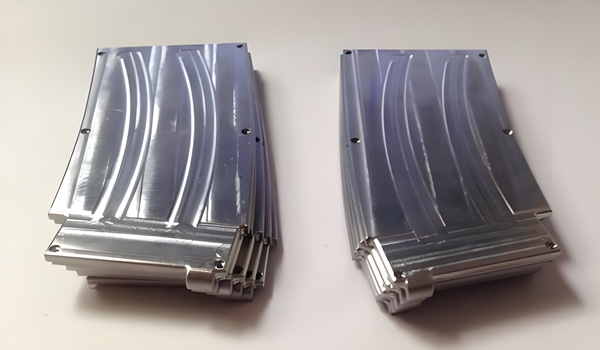

High Precision Stability (Tolerance ±0.02 ~ ±0.05 mm): Strong Thermal Control as a Key Enabler

This tolerance range is common for:

- Industrial automation components

- Precision instrument housings

- High-quality connectors and interfaces

While a fully isolated temperature-controlled room may not always be required, overall workshop temperature stability remains critical. Professional manufacturing environments typically rely on:

- Centralized HVAC systems to limit temperature fluctuation (e.g., within ±2°C)

- Machine warm-up procedures to reach thermal equilibrium

- Efficient coolant systems to manage cutting heat

- Process planning that separates rough machining and finishing operations

In this range, temperature control is a major contributor to consistency and repeatability.

Standard Precision (Tolerance ≥ ±0.1 mm): Minimal Temperature Sensitivity

For structural parts, cosmetic components, or non-critical assemblies, dimensional changes caused by normal temperature variation typically remain within acceptable limits.

Basic controls—such as avoiding extreme temperature swings, direct sunlight, and strong air drafts—are usually sufficient.

Practical Guidance for Buyers: How to Communicate Effectively with Machining Partners

Identify Critical Tolerances

If multiple key dimensions fall within ±0.02 mm, temperature control should be discussed early in the project.

Assess Process Infrastructure

Beyond machine capability, evaluate environmental and inspection conditions by asking questions such as:

- How is workshop temperature controlled?

- Is precision inspection performed in a temperature-stable environment?

A qualified machining partner should be able to clearly explain these controls.

Balance Performance and Cost

Temperature-controlled facilities require significant investment and operating cost, which will be reflected in pricing. Precision should always be driven by functional necessity, not over-specification.

Conclusion

In modern precision manufacturing, temperature-controlled workshops—or highly stable thermal environments—form the foundation of reliable high-precision aluminum CNC machining.

This is not a marketing concept, but a requirement rooted in material physics and machining principles.

For buyers, understanding this relationship enables better supplier evaluation and cost-to-performance decisions. For manufacturers, continued investment in environmental control is a critical step toward advanced precision manufacturing and long-term trust.