In the field of precision manufacturing, especially in the design and production of robots, material selection exerts a decisive impact on performance, service life and stability. As reflected in the trending discussion of the video Why Do Robot Structural Components Opt for High-performance 7075 Aluminum Alloy?, 7075 aluminum alloy has become the preferred material for numerous robot components. This choice is not merely based on cost considerations, but more importantly, a scientific decision that aligns the physical and chemical properties of the material perfectly with the application requirements of robots.

Table of Contents

ToggleCore Advantages of 7075 Aluminum Alloy

As a high-strength aluminum alloy, 7075 aluminum alloy is characterized by the following key aspects:

- Excellent Combination of High Strength and LightweightAfter heat treatment (e.g., T6 temper), 7075 aluminum alloy can achieve a tensile strength of over 500 MPa, far exceeding that of many common aluminum alloys (such as 6061).Its high specific strength (the ratio of strength to density) ensures structural stability while significantly reducing weight, which is crucial for robot joints and frames that demand high mobility and low energy consumption.

- Superior Fatigue ToughnessRobot components often operate under conditions of high-frequency movement and vibration loads, requiring materials with good fatigue resistance.The dense microstructure of 7075 aluminum alloy can effectively inhibit crack propagation, extending the service life of structural parts under cyclic loading.

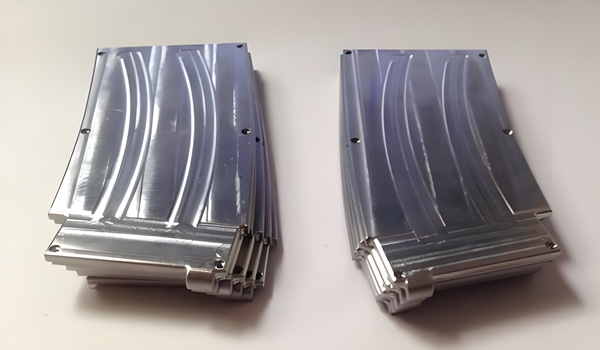

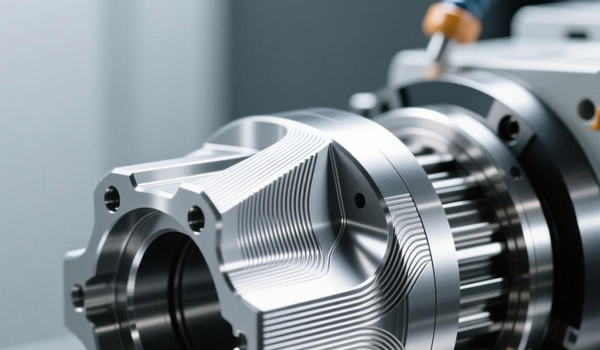

- Good Machinability and Surface Treatment CompatibilityDespite its high hardness, 7075 aluminum alloy can still be formed into complex structures through precision machining methods like CNC machining, meeting the high-precision requirements of robot parts.Its surface can be easily subjected to treatments such as anodization and spraying, enhancing corrosion resistance, aesthetics and additional functions (e.g., insulation and wear resistance).

- Corrosion Resistance and StabilityBy adding alloying elements such as zinc, magnesium and copper, 7075 aluminum alloy maintains high strength while possessing good stress corrosion resistance, making it suitable for diverse operating environments (including industrial settings and outdoor applications).

Why Is This High-performance Material Particularly Needed in the Robotics Field?

- Dynamic Load and Precision RequirementsStructural components like robot joints and arm bodies bear multi-directional forces and torques during movement. High-rigidity materials can minimize deformation, ensuring positioning accuracy and control stability.Compared with ordinary aluminum alloys or steel, 7075 aluminum alloy offers higher rigidity with lightweight features, helping to improve the motion response speed and energy efficiency of robots.

- Reliability and SafetyIndustrial or service robots often need to run continuously for long periods. Material failure may lead to serious accidents. The high fatigue strength and stability of 7075 aluminum alloy reduce the risk of unexpected malfunctions, complying with the design standards of high-reliability equipment.

- Balance Between Long-term Cost and PerformanceAlthough the unit material cost is relatively high, the overall life-cycle cost is often more advantageous by reducing structural weight, improving energy efficiency and extending replacement cycles.In fields such as high-end robots, aerospace robots and precision automation equipment, performance is often prioritized over initial material costs.

Application Scenarios

- Industrial Robot Arm Joints: Require high strength to support high-speed rotation and load-bearing.

- Drone/Mobile Robot Frames: Need to balance lightweight design with impact resistance.

- Precision Instrument Bearing Structures: Demand low thermal expansion coefficient and high dimensional stability.

- Bionic Robot Exoskeletons: Need to combine strength, elasticity and light weight to simulate biological joints.

Conclusion

The selection of 7075 aluminum alloy for manufacturing robot structural components is not a blind pursuit of high cost, but based on its comprehensive properties including high strength, lightweight design, fatigue resistance and machining friendliness. These properties are highly compatible with the stringent requirements of robots for precision, reliability and durability. As robot technology advances toward high speed, high load and high precision, such high-performance materials will continue to serve as the cornerstone of high-end equipment manufacturing, driving the entire industry toward a more reliable and intelligent future.