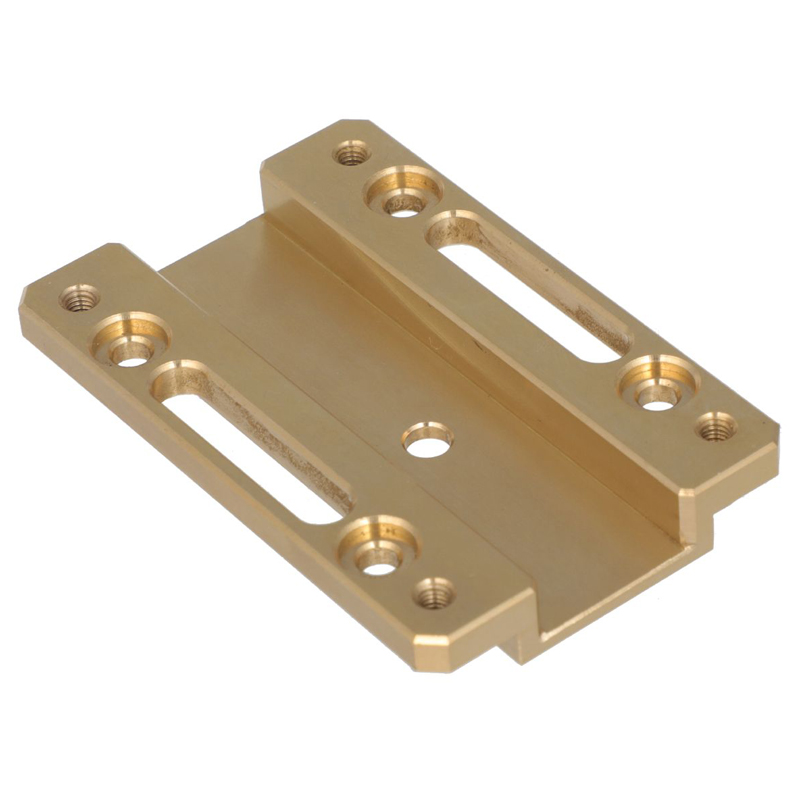

Fixture System Adapter Plate – CNC Machined for Module Positioning

Description

The Fixture Adapter Plate is a core component in custom workholding and fixture systems, designed specifically for optoelectronic and semiconductor equipment modules. Manufactured from high-quality C36000 brass, this plate provides excellent thermal conductivity, electrical conductivity, and wear resistance, making it ideal for precision alignment and module mounting.

Key Features & Benefits:

-

Precision Alignment: Accurately positions modules within optical, laser, or vision systems with micron-level tolerance.

-

Customizable Dimensions: Overall size, hole placement, and slotted or threaded features can be tailored to your fixture system.

-

Robust Manufacturing: Produced using 3-axis/4-axis CNC milling, drilling, and tapping, followed by optional surface treatments such as passivation or gold plating.

-

Functional Versatility: Slotted holes enable fine positional adjustments (±2 mm), ensuring perfect alignment during assembly.

-

High-Quality Standards: Each plate undergoes CMM dimensional inspection, roughness testing, and visual defect checks, meeting ISO 9001 or customer-specific tolerances.

-

Flexible Production: Available in single-unit prototypes or high-volume production runs, with fast lead times (3–5 days for prototypes; 7–10 days for mass production).

Applications:

This adapter plate is ideal for laser modules, vision cameras, optical sensors, and other precision equipment requiring stable, repeatable positioning within a fixture. Its combination of material properties, precise machining, and functional design makes it a reliable choice for both prototyping and industrial-scale assembly.

| Category | Specification | Notes |

|---|---|---|

| Basic Information | Part Name: Fixture Adapter PlateSystem: Custom Fixture/Jig SystemApplication: Optoelectronic / Semiconductor Module Positioning & Mounting | Core component of custom workholding fixtures |

| Material & Surface Finish | Base Material: Brass (C36000)Surface Treatment: Passivation / Gold Plating (Optional)Hardness: HV120–150 | Brass offers excellent thermal and electrical conductivity, and high wear resistance |

| Manufacturing Process | Primary Processes: CNC Precision Milling, Drilling, Tapping, DeburringSecondary Processes: Surface Grinding, Ultrasonic Cleaning | 3-axis/4-axis CNC machining centers ensure high dimensional consistency |

| Critical Dimensions | Overall Dimensions (Typical): L120 × W80 × H10 mmLocating Hole Diameter: φ6H7 (Tolerance ±0.01 mm)Slotted Hole: L30 × W8 mmThreaded Hole: M4/M5 (Depth 8–10 mm) | Fully customizable to meet fixture system requirements |

| Precision Requirements | Flatness: ≤0.02 mmParallelism: ≤0.03 mmHole Position Tolerance: ≤0.015 mmSurface Roughness: Ra ≤0.8 μm (mounting surfaces) / Ra ≤1.6 μm (non-mating surfaces) | Meets micron-level alignment needs of optoelectronic equipment |

| Functional Features | Core Functions: Module Positioning & Mounting, Heat Conduction, Fine Positional AdjustmentUse Case: Workholding fixture for laser modules / vision cameras | Slotted holes allow ±2 mm positional adjustment for precise alignment |

| Inspection Standards | Inspection Items: CMM Dimensional Inspection, Roughness Test, Visual Defect CheckAcceptance Criteria: ISO 9001 / Customer Drawing Tolerances | Complete dimensional inspection report provided with shipment |

| Production Details | Minimum Order Quantity: 1 unit (Prototype) / 50 units (Mass Production)Lead Time: 3–5 days (Prototype) / 7–10 days (Mass Production) | Supports low-volume customization and high-volume production |

Additional information

| material |

|---|

Reviews

There are no reviews yet.