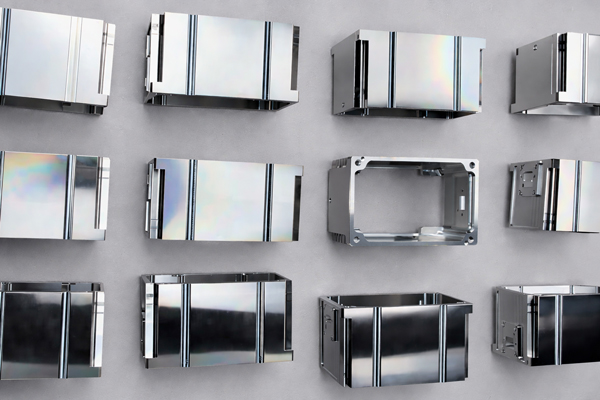

In the field of metal processing, aluminum alloy exterior parts with high-gloss, mirror-like finishes have long garnered attention. Many wonder how such an exquisite, nearly mirror-perfect texture is achieved. In fact, with the continuous advancement of processing technology, creating such high-gloss surfaces is no longer an insurmountable challenge—yet it relies heavily on precise control over cutting tools, equipment, and process management.

A key factor in achieving a mirror-like high-gloss effect lies in the selection of cutting tools. Typically, equipping BCT large cutters for machining can initially produce a basic high-gloss texture. For smaller cutters, however, higher machine spindle speeds are required: high-speed machines with over 3,000 rpm and pneumatic spindles exceeding 60,000 rpm are ideal choices. In particular, high-gloss machines paired with diamond cutters can deliver consistent mirror-like results without complex operations, making sufficient spindle speed a key prerequisite for the high-gloss finish.

Beyond tools and speed, three core considerations must not be overlooked during the machining process. First is the stability of workpiece clamping: the workpiece must be firmly fixed to avoid “tool chatter” caused by loose clamping. This is why many manufacturers opt for the sequence of “machining the exterior first, then refining the interior.” Second is machine rigidity—insufficient rigidity directly impacts machining precision, as seen in ordinary drilling and tapping machines that struggle to achieve optimal results in high-gloss processing. Third is tool accuracy control: minimizing tool deviation is essential, and installing a tool holder is recommended to ensure consistent machining quality.

When discussing industry benchmarks in high-gloss processing, mention must be made of Beijing Jindiao, “a source of pride in domestic manufacturing” more than a decade ago. Back then, Beijing Jindiao gained widespread acclaim in the high-gloss processing of Apple’s phone casings through its innovative configuration of single-crystal PCD fly-cutters paired with marble machine bases. Its machines were remarkably heavy—an ordinary 500-model unit weighed five to six tons. This robust design provided a solid foundation for machining precision and surface finish, even outperforming Japanese and German counterparts in the high-gloss sector, ultimately winning Apple’s trust. However, due to its design philosophy, Beijing Jindiao’s machines were relatively low in efficiency and high in cost, leading to limited adoption in ordinary factories.

If tools and equipment are the “hardware foundation” of high-gloss processing, process management is the “software core” that determines final quality. High-gloss aluminum alloy parts often require direct oxidation without sandblasting, demanding zero scratches throughout the entire production process. When a client once proposed this requirement, the processing team went through nearly six months of repeated adjustments. During the initial attempt, the yield rate of products with zero scratches—from machining to oxidation—was less than 5%. Yet both the client and the team persevered. Through continuous optimization of operational procedures and refined protective measures, they have finally increased the yield rate to over 90%.

Today, aluminum alloy high-gloss processing technology has matured significantly. A suitable diamond cutter and a machine with sufficient spindle speed are all it takes to take the first step toward creating a high-gloss finish. But the real difference between ordinary and exceptional results lies in the dedication to details—from the stability of workpiece clamping and tool accuracy control to equipment selection and scratch-proof protection throughout the process. Striving for excellence in every link is the key to achieving high-quality, mirror-like high-gloss finishes. This commitment to quality is not only the original aspiration of the processing industry but also the driving force behind continuous technological progress.