High-Efficiency Cooling Fan Impeller for Industrial Motor Applications

Description

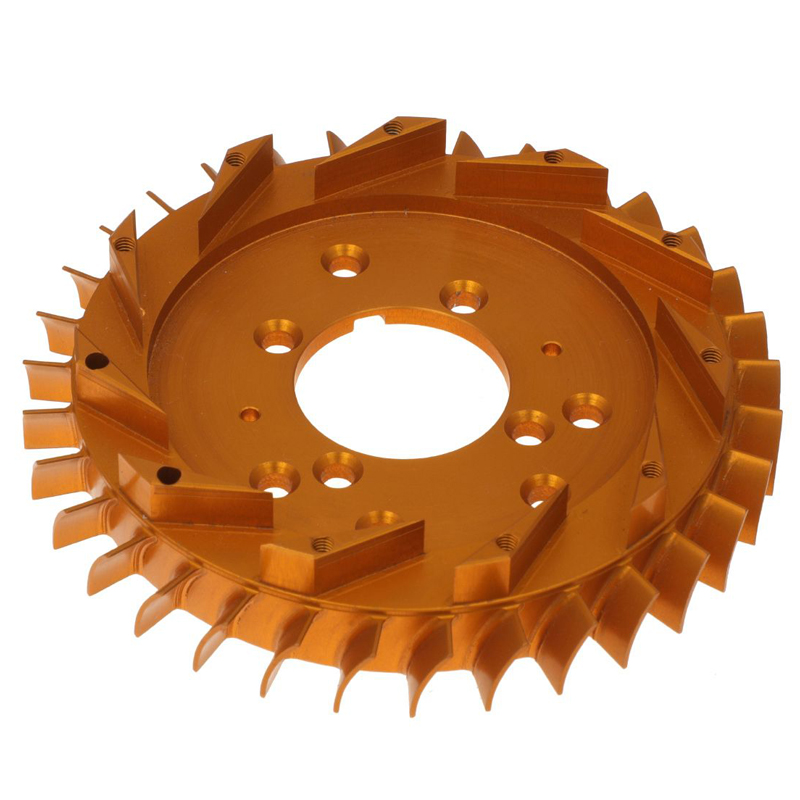

5-Axis CNC Machined Micro High-Speed Cooling Fan Impeller | G2.5 Dynamic Balance, Custom Cooling Component for Micro Servo Motors

As a core cooling part for micro precision power equipment, this 5-axis CNC machined micro high-speed cooling fan impeller is tailor-made for compact, high-speed micro devices. With exceptional precision and stable heat dissipation performance, it stands as the preferred precision component to solve “high-temperature overload and vibration noise” pain points in micro servo motors and micro turbochargers.

1. 5-Axis CNC Simultaneous Machining: Military-Grade Precision Quality

Crafted on DMG/Mazak 5-axis CNC machining centers, we adopt a composite process of “5-axis simultaneous milling + precision turning + high-pressure air deburring” to ensure quality from the source:

- Extreme precision control: ±0.01mm tolerance for blade profiles and ±0.005mm for shaft hole positioning datums, perfectly fitting the narrow installation space of micro devices for seamless integration.

- Premium material options: 6061-T6 aluminum alloy (lightweight + high heat dissipation) as standard; 7075-T6 high-strength aluminum alloy (for high-speed applications) or brass (for special cooling scenarios) available upon request.

- Customizable surface treatments: Anodization (gold/natural color, enhanced corrosion resistance), passivation, sandblasting, etc., balancing heat dissipation efficiency and aesthetic adaptability.

2. G2.5 Dynamic Balance: Stable Operation at Up to 15,000RPM

Engineered for the high-speed operation needs of micro devices, the product achieves three key advantages—”low vibration, high efficiency, and long lifespan”—through structural optimization and rigorous testing:

- High-speed compatibility: Supports continuous operation at ≤15,000RPM, precisely matching the working conditions of micro servo motors and micro turbochargers.

- Strict dynamic balance standard: Complies with G2.5 dynamic balance grade, with blade residual unbalance ≤0.5g·mm, eliminating vibration and noise during high-speed operation.

- Excellent fatigue resistance: 6061-T6 aluminum alloy offers tensile strength ≥290MPa and hardness ≥95HB, combining lightweight design with fatigue resistance to extend overall equipment service life.

3. Core Applications: Micro Servo Motors & Precision Instruments

Widely used in core sectors including automation, power equipment, and precision instruments, with key applications in:

- Built-in cooling modules for micro servo motors in 3C automation lines (e.g., chip mounters, micro robotic arms).

- Auxiliary cooling systems for micro turbochargers in motorcycles and small generators.

- Internal cooling devices for precision instruments such as micro laser markers and laboratory micro chromatographs.

4. Full-Scale Customization & ISO9001 Certification: Adaptable to Multi-Batch Purchases

Leveraging mature CNC machining capacity, we provide flexible customization and end-to-end quality control to meet diverse procurement needs:

- Full-size customization: Blade quantity (8-12 pieces), impeller diameter (φ25mm-φ90mm), shaft hole diameter (φ5mm-φ15mm); full-size machining supported based on customer 3D drawings (STEP/IGS formats).

- Multi-batch delivery: Rapid prototyping for small batches (1-50 pcs), stable delivery for medium batches (50-500 pcs), and cost-effective mold blank + CNC finishing solutions for mass production (500+ pcs).

- Authoritative quality assurance: Complies with ISO9001:2015 standards; free dynamic balance test reports provided; 100% full-size inspection for each batch using coordinate measuring machines (CMM).

Contact us today to discuss your custom requirements—we deliver precision, reliability, and tailored solutions for your micro cooling needs!

| Category | Parameter Item | Standard Value / Service Capability |

|---|---|---|

| Basic Product Info | Product Name | Micro High-Speed Cooling Fan Impeller |

| Core Application | Internal cooling for micro servo motors / micro turbochargers / precision instruments | |

| Applicable Equipment Size Range | φ30mm-φ80mm (for micro power equipment) | |

| CNC Machining Process | Machining Material | 6061-T6 Aluminum Alloy (default) / 7075-T6 Aluminum Alloy (high-strength demand) / Brass (special cooling scenarios) |

| Machining Equipment | 5-axis CNC Machining Center (DMG/Mazak) | |

| Machining Process | 5-axis simultaneous milling (complex surface forming) + precision turning (shaft hole positioning) + deburring (high-pressure airflow + manual finishing) | |

| Surface Treatment | Anodizing (gold/natural color, default) / Passivation / Sandblasting (customizable) | |

| Precision Control | Dimensional Tolerance | ±0.01mm (blade profile); ±0.005mm (shaft hole positioning datum) |

| Geometric Tolerance | Roundness ≤0.003mm (shaft hole); Flatness ≤0.008mm (mounting end face) | |

| Surface Roughness | Ra1.6μm (blade surface); Ra3.2μm (non-mating surface) | |

| Dynamic Balance Grade | G2.5 (suitable for ≤15000RPM high-speed scenarios) | |

| Performance Guarantee | Maximum Adaptable Rotational Speed | ≤15000RPM (for aluminum alloy material) |

| Residual Dynamic Balance of Blades | ≤0.5g·mm (vibration-free operation at high speed) | |

| Mechanical Properties of Material | 6061-T6: Tensile strength ≥290MPa; Hardness ≥95HB (meets high-speed rotation strength requirements) | |

| Customization Service | Size Customization Range | Blade quantity: 8-12 pieces; Impeller diameter: φ25mm-φ90mm; Shaft hole diameter: φ5mm-φ15mm |

| Batch Support | Small batch (1-50 pcs) / Medium batch (50-500 pcs) / Mass production (500+ pcs, mold blank + CNC finishing for cost reduction) | |

| Additional Services | 1 free dynamic balance test report; Full-size machining supported by customer 3D drawings (STEP/IGS format) | |

| Testing Standard | Testing Equipment | Coordinate Measuring Machine (accuracy ±0.002mm) / Dynamic Balance Tester / Surface Roughness Tester |

| Quality Standard | ISO9001:2015; Complies with precision machining industry standards for automation equipment components |

Additional information

| material |

|---|

Reviews

There are no reviews yet.